Boosting E-Commerce Fulfillment with Smarter Logistics Center Strategies

Author:XTransfer2025.12.17Logistics center

In the fast-paced world of e-commerce, the logistics center plays a critical role in ensuring smooth operations. Optimization of these centers directly impacts your ability to meet customer expectations. For instance, smarter logistics strategies can reduce delivery times by up to 30% and improve order fulfillment capacity by 40% during peak periods. Enhanced route planning and real-time tracking also boost efficiency, leading to fewer delays and higher customer satisfaction. By adopting advanced tools like warehouse management systems and predictive analytics, you can achieve faster fulfillment while enhancing customer satisfaction and reducing operational costs.

The Role of Logistics Centers in E-Commerce

Defining logistics centers and their importance

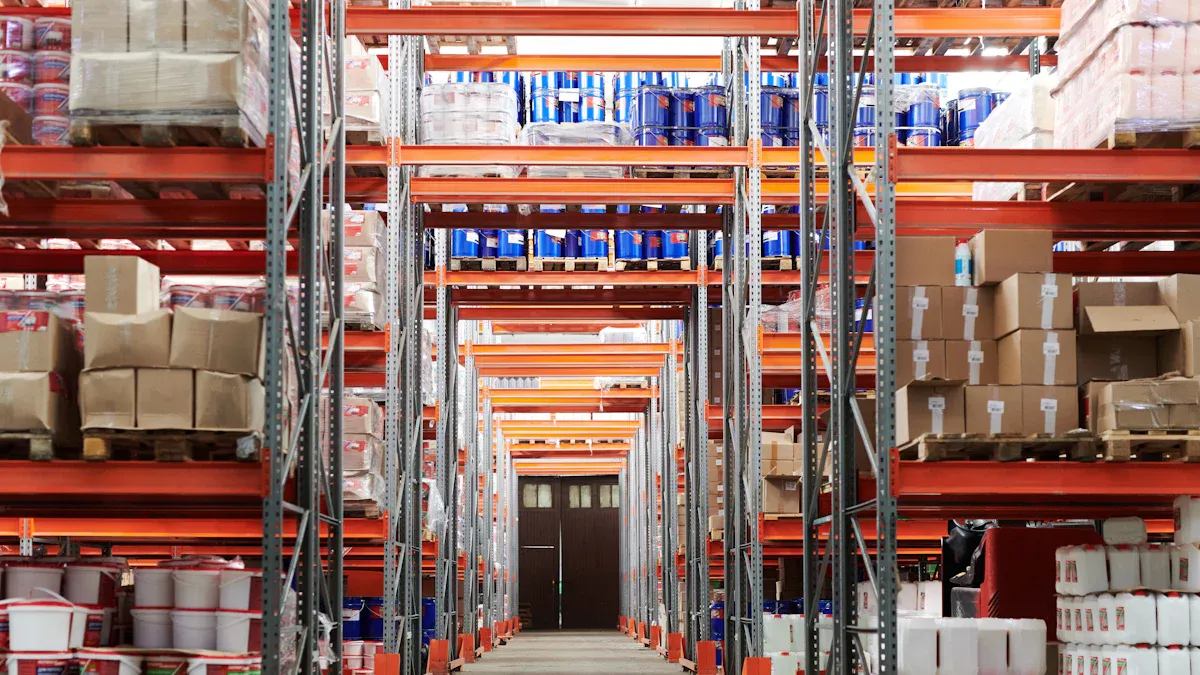

A logistics center serves as the backbone of your e-commerce operations. It acts as a hub where products are stored, processed, and prepared for delivery to customers. These centers streamline the flow of goods, ensuring that orders are fulfilled quickly and accurately. Without them, managing the complexities of e-commerce logistics would become overwhelming.

Logistics centers also play a vital role in reducing costs. By centralizing operations, you can optimize inventory management and minimize shipping expenses. This efficiency not only benefits your business but also enhances the customer experience by ensuring faster delivery times.

Key functions in e-commerce fulfillment

Logistics centers handle several critical tasks that keep your e-commerce business running smoothly. One of their primary functions is inventory management. They store products in an organized manner, making it easier to track stock levels and avoid shortages. This ensures that your customers can always find what they need.

Order processing is another essential function. Once a customer places an order, the logistics center picks, packs, and prepares the items for shipment. This process requires precision to ensure that the correct products reach the right customers.

Shipping and last-mile delivery are also managed through logistics centers. By coordinating with carriers, these centers ensure that packages are delivered on time. This step is crucial for maintaining customer satisfaction and building trust in your brand.

Finally, logistics centers help you adapt to seasonal demand fluctuations. During peak shopping periods, such as holidays, they scale operations to handle increased order volumes efficiently. This flexibility keeps your e-commerce supply chain resilient and responsive.

Challenges in E-Commerce Logistics

Inventory management and stock availability

Effective inventory management is crucial for e-commerce logistics. You need to ensure that stock levels align with customer demand to avoid stockouts or overstocking. Stockouts can lead to lost sales and damage customer trust, while overstocking increases storage costs and ties up working capital. Seasonal demand fluctuations further complicate inventory planning, making it essential to adopt real-time inventory tracking systems.

|

Inventory Issue |

Impact on Business Performance |

|---|---|

|

Stockouts |

Loss of immediate sales and damage to customer trust |

|

Overstocking |

Increased storage costs and tied-up working capital |

|

Inaccurate Forecasting |

Misjudgment of future demand leading to stockouts or overstock |

|

Supply Chain Disruptions |

Complications affecting inventory plans |

|

Seasonal Volatility |

Challenges in inventory planning due to demand fluctuations |

|

Multi-channel Mayhem |

Synchronization issues across different selling platforms |

Inventory optimization tools can help you address these challenges. By leveraging predictive analytics and automation, you can forecast demand more accurately and streamline inventory management across multiple channels.

Streamlining order processing and picking

Streamlining order processing is vital for improving operational efficiency. When you optimize picking routes and use tools like picking carts, you reduce travel time and increase picking speed. This leads to faster order fulfillment and enhances worker productivity.

-

Increased Picking Speed: Optimized routes and picking carts reduce picker time and travel, enabling faster fulfillment.

-

Reduced Travel Time: Picking carts allow workers to move more items with fewer trips, minimizing unnecessary movement.

-

Improved Ergonomics: Ergonomic designs of picking carts improve worker well-being, reducing injuries and turnover rates.

Order processing automation further enhances efficiency. By automating repetitive tasks, you can reduce errors and accelerate the packing process. This ensures that customers receive their orders promptly and accurately.

Managing shipping and last-mile delivery

Shipping and last-mile delivery are among the most challenging aspects of e-commerce logistics. You need to ensure timely deliveries while minimizing costs. Technology plays a pivotal role in optimizing delivery and shipping processes. AI and machine learning algorithms can optimize delivery routes, reducing delays and providing real-time tracking updates. Automation tools like drones and robotics enhance delivery speed and accuracy.

-

AI-powered route optimization minimizes delays and improves efficiency.

-

Real-time tracking builds customer trust and reduces complaints.

-

Automation tools streamline delivery operations, ensuring accuracy.

-

Data analytics identifies inefficiencies and supports better inventory management.

Partnering with third-party logistics providers (3PLs) can also help you scale operations efficiently. These providers offer services like contract logistics and returns processing, enabling you to focus on core business activities. The hub-and-spoke network model further enhances last-mile delivery by centralizing warehousing and optimizing daily dispatches.

Addressing seasonal demand fluctuations.

Seasonal demand fluctuations can significantly impact your e-commerce operations. During peak shopping periods, such as Black Friday or the holiday season, order volumes often surge. Without proper planning, these spikes can overwhelm your logistics center, leading to delays, stockouts, and dissatisfied customers. To stay ahead, you need strategies that help you adapt quickly and efficiently.

One effective approach is to forecast demand using data-driven models. By analyzing historical sales data, you can predict when demand will rise and adjust your inventory levels accordingly. For example, the formula I = D + σ⋅Φ−1(p) helps calculate optimal inventory levels by factoring in demand and forecast uncertainty. This ensures you stock enough products to meet customer needs without overloading your warehouse.

|

Formula |

Description |

|---|---|

|

|

Represents optimal inventory level based on demand and forecast uncertainty. |

|

|

Quantifies the relationship between sales, weather, and seasonal trends. |

Flexibility in staffing is another key factor. Hiring temporary workers during peak seasons can help you manage increased workloads. Cross-training your existing staff also ensures they can handle multiple tasks, such as picking, packing, and shipping, during high-demand periods.

Finally, consider diversifying your fulfillment network. Micro-fulfillment centers or partnering with third-party logistics providers can help you distribute inventory closer to customers. This reduces delivery times and ensures smoother operations during seasonal peaks. By preparing in advance, you can turn seasonal demand fluctuations into opportunities for growth.

Strategies for Logistics Optimization

Leveraging technology and automation

Technology and automation are transforming the way logistics centers operate. By integrating advanced tools, you can significantly enhance accuracy and efficiency in your e-commerce logistics processes. Automated systems, such as robotic picking and packing solutions, streamline operations and reduce human error. For example, robotic picking systems can achieve over 98% order accuracy, ensuring that customers receive the correct items every time.

Automation also reduces labor costs and boosts productivity. Tasks like sorting, packing, and shipping can be handled by machines, allowing your workforce to focus on more complex responsibilities. This not only saves time but also improves overall system uptime, ensuring smooth operations even during peak periods. Additionally, automated solutions have been shown to increase repeat customer orders by 30%, as they enhance the reliability of order fulfillment.

|

Metric |

Improvement/Impact |

|---|---|

|

Order Fulfillment Accuracy |

Up to 99% accuracy with advanced robotics |

|

Repeat Customer Orders |

30% increase with automated solutions |

|

Order Accuracy Rate |

Over 98% with robotic picking systems |

|

Labor Cost Savings |

Significant reduction through automation |

|

System Uptime |

High innovation rate indicates efficiency |

|

Customer Satisfaction Scores |

Enhanced through improved order accuracy |

By leveraging automation, you can also implement advanced tracking systems. These systems provide real-time updates on inventory levels and shipping statuses, enabling you to make informed decisions quickly. This level of transparency builds trust with your customers and ensures a seamless shopping experience.

Optimizing warehouse layouts for efficiency

An optimized warehouse layout is essential for reducing fulfillment times and costs. By reimagining your logistics center's design, you can maximize space utilization and streamline workflows. For instance, using vertical storage solutions increases storage capacity without requiring additional physical space. This approach is particularly beneficial for e-commerce businesses dealing with high inventory volumes.

Studies show that warehouses with optimized layouts can reduce picking and travel times by 20-30%. This directly translates to faster order fulfillment and lower operational costs. To achieve this, you can follow these steps:

-

Maximize the use of available space through intelligent layout redesign.

-

Implement high-density storage solutions to increase capacity.

-

Strategically place inventory based on demand velocity to enhance operational flow.

Conducting traffic flow analysis is another effective strategy. By identifying congestion areas, you can minimize unnecessary movement and speed up operations. This not only improves efficiency but also reduces the risk of workplace accidents. Ultimately, an optimized layout ensures that your logistics center operates at peak performance, even during high-demand periods.

Data-driven decision-making for forecasting

Data-driven decision-making is a game-changer for logistics optimization. By utilizing big data and advanced analytics, you can forecast demand more accurately and manage your inventory effectively. Predictive analytics, for example, allows you to identify trends and anticipate customer needs, ensuring that your inventory levels align with market demand.

This approach also helps you mitigate risks in your ecommerce supply chain. For instance, by analyzing historical sales data, you can prepare for seasonal demand fluctuations and avoid stockouts or overstocking. Companies that adopt data-driven forecasting models often see significant improvements in operational efficiency and cost savings.

Predictive analytics enhances decision-making capabilities, enabling you to optimize supply chain processes. This leads to better inventory management, reduced costs, and improved customer satisfaction. By integrating data analytics for inventory management into your logistics center, you can stay ahead of market changes and maintain a competitive edge in the e-commerce industry.

Partnering with third-party logistics providers.

Collaborating with third-party logistics providers (3PLs) can transform your e-commerce operations. These partnerships allow you to leverage the expertise and infrastructure of specialized logistics companies, enabling you to focus on your core business activities. By outsourcing complex logistics tasks, you can achieve greater efficiency and scalability.

Here are some key benefits of partnering with 3PLs:

-

Enhanced visibility into inventory improves inventory control and stock optimization.

-

Streamlined logistics operations lead to significant cost savings.

-

Access to advanced technologies, such as real-time inventory tracking and demand forecasting, enhances operational efficiency.

-

Reduced overhead costs eliminate the need to own and manage warehousing and shipping infrastructure.

-

Flexibility and scalability allow you to adapt to fluctuating business demands with ease.

For example, a 3PL provider can use automation tools to optimize your fulfillment processes. These tools include warehouse management systems and route optimization software, which reduce errors and improve delivery times. Additionally, 3PLs often operate extensive networks of warehouses and distribution centers, enabling faster last-mile delivery to your customers.

By integrating a 3PL into your logistics strategy, you can also improve customer satisfaction. Faster delivery times, accurate order tracking, and reliable service build trust and encourage repeat purchases. This partnership not only supports your logistics optimization efforts but also strengthens your brand reputation in the competitive e-commerce market.

Training staff for operational excellence.

Your workforce plays a critical role in achieving fulfillment optimization. Well-trained employees ensure that your logistics center operates efficiently and meets customer expectations. Investing in staff training programs enhances their skills and boosts overall productivity.

Training programs improve several performance metrics:

|

Performance Metric |

Improvement Observed |

|---|---|

|

Employee Engagement |

Enhanced |

|

Process Efficiency |

Streamlined |

|

Overall Operational Efficiency |

Better |

Companies with structured training programs often experience 24% higher profit margins compared to those without. This demonstrates the direct impact of training on business success.

To achieve operational excellence, focus on cross-training your staff. This approach equips employees with the skills to handle multiple tasks, such as picking, packing, and shipping. Cross-training not only increases flexibility during peak periods but also reduces downtime caused by staff shortages.

Incorporating technology into training programs further enhances their effectiveness. For instance, virtual reality (VR) simulations can teach employees how to navigate warehouse layouts or operate automated systems. This hands-on experience prepares them for real-world challenges and minimizes errors during operations.

Regular performance evaluations and feedback sessions also play a vital role. By identifying areas for improvement, you can tailor training programs to address specific needs. This continuous learning approach ensures that your workforce remains adaptable and capable of handling the evolving demands of e-commerce logistics.

Emerging Trends in E-Commerce Logistics

AI and machine learning in logistics

AI and machine learning are revolutionizing e-commerce logistics by improving efficiency and decision-making. These technologies analyze vast amounts of data to optimize processes like route planning and inventory management. For example, AI-powered algorithms reduce empty miles in transportation from 30% to as low as 10-15%. This optimization not only saves fuel but also cuts costs significantly.

AI models also enhance supply chain agility. They predict demand trends, helping you stock the right products at the right time. This reduces the risk of stockouts or overstocking, ensuring your customers always find what they need. Additionally, AI technologies streamline warehouse operations by automating repetitive tasks, allowing your team to focus on high-value activities.

|

Improvement Type |

Quantitative Result |

|---|---|

|

Reduced Empty Miles |

From 30% to 10-15% |

|

Optimized Routing |

Algorithmically designed routes for efficiency |

By adopting AI and machine learning, you can stay competitive in the fast-paced e-commerce industry. These tools not only improve operational efficiency but also enhance customer satisfaction through faster and more accurate deliveries.

Robotics and automation in fulfillment

Robotics and automation are transforming fulfillment processes in e-commerce logistics. Robots handle repetitive tasks like picking and packing, which speeds up order processing and reduces errors. For instance, automated systems increase pick rates and optimize pick routes, enabling faster execution of routine tasks. This directly improves order fulfillment speeds and enhances customer satisfaction.

-

Robots reduce the time required for repetitive tasks, increasing throughput.

-

Automated systems streamline workflows, resulting in faster order fulfillment and fewer errors.

-

Robotics create new opportunities for logistics companies by enhancing operational capabilities.

By integrating robotics into your logistics center, you can achieve higher efficiency and accuracy. Employees can focus on quality control and customer service while robots handle tedious tasks. This balance leads to a more productive and reliable fulfillment process.

Sustainability in logistics operations

Sustainability is becoming a key focus in e-commerce logistics. Consumers increasingly prefer brands that prioritize eco-friendly practices. For example, 73% of shoppers are more likely to support companies with sustainable operations. Adopting green strategies not only benefits the environment but also gives you a competitive edge.

You can implement several sustainability measures in your logistics operations:

-

Optimize route planning with GPS and AI to reduce fuel consumption.

-

Transition to renewable energy sources for powering warehouses.

-

Invest in energy-efficient vehicles and equipment.

-

Minimize waste by adopting recycling and reuse practices.

These strategies reduce carbon emissions and improve fuel efficiency, making your operations more environmentally friendly. By prioritizing sustainability, you can align your business with consumer values and contribute to a greener future.

Micro-fulfillment centers for faster delivery.

Micro-fulfillment centers (MFCs) are revolutionizing the way ecommerce businesses handle order fulfillment. These compact, strategically located facilities bring products closer to your customers, enabling faster deliveries and improved service quality. By adopting MFCs, you can optimize your logistics operations and meet the growing demand for speed and convenience in e-commerce.

How Micro-fulfillment Centers Work

Unlike traditional warehouses, MFCs focus on storing high-demand products in smaller spaces near urban areas. This proximity reduces the distance between your inventory and your customers, allowing you to fulfill orders more quickly. Advanced automation and robotics further enhance the efficiency of these centers, ensuring that orders are processed and dispatched with minimal delays.

Benefits of Micro-fulfillment Centers

Micro-fulfillment centers offer several advantages that can transform your logistics strategy. Here’s how they contribute to faster and more efficient deliveries:

|

Benefit |

Description |

|---|---|

|

Quicker Delivery Times |

Products travel shorter distances, reducing delivery times significantly. |

|

Accurate Delivery Windows |

Advanced tracking systems ensure precise delivery schedules, enhancing customer satisfaction. |

|

Same-Day or Next-Day Delivery |

MFCs enable you to offer fast delivery options, meeting consumer expectations for speed. |

|

Reduced Last-Mile Delivery Costs |

Shorter delivery routes lower transportation expenses, saving you money. |

|

Improved Inventory Management |

Better stock tracking minimizes stockouts and overstocking, reducing returns and associated costs. |

By leveraging these benefits, you can enhance your ecommerce fulfillment process and build stronger customer loyalty.

Why Micro-fulfillment Centers Are Essential for Optimization

Incorporating MFCs into your logistics network is a smart optimization strategy. These centers streamline operations by reducing the time and cost associated with last-mile delivery. For example, storing products closer to your customers minimizes transportation distances, which not only speeds up deliveries but also lowers fuel consumption. This approach aligns with the growing demand for sustainable logistics practices.

Additionally, MFCs improve inventory management by using real-time tracking systems. These systems help you monitor stock levels accurately, ensuring that you always have the right products available. This reduces the risk of stockouts, which can lead to lost sales, and overstocking, which ties up valuable resources.

Meeting Consumer Expectations with Fast Deliveries

Today’s e-commerce customers expect fast deliveries, often within the same day. Micro-fulfillment centers make this possible by enabling you to process and ship orders quickly. With advanced automation, these centers can handle high order volumes efficiently, even during peak shopping periods. This ensures that your customers receive their orders on time, boosting satisfaction and encouraging repeat business.

By adopting micro-fulfillment centers, you can transform your logistics operations, meet customer expectations, and drive long-term growth in the e-commerce industry.

Optimizing your logistics center is essential for achieving success in e-commerce. It improves operational performance and enhances customer satisfaction. By adopting strategies like automation, data-driven forecasting, and micro-fulfillment centers, you can streamline fulfillment processes and meet growing consumer demands. Emerging trends such as AI, robotics, and sustainability further strengthen your logistics capabilities.

The benefits of logistics center optimization extend beyond efficiency. They build trust, encourage repeat purchases, and reduce costs. The table below highlights these advantages:

|

Benefit |

Description |

|---|---|

|

Builds trust with customers |

Enhances customer confidence in the e-commerce service. |

|

Encourages repeat purchases |

Satisfied customers are more likely to return for future purchases. |

|

Minimizes negative feedback |

Reduces the likelihood of complaints, improving overall customer experience. |

|

Reassures customers |

Ensures customers feel valued and prioritized, leading to higher satisfaction. |

|

Greater customer loyalty and retention |

Optimized logistics contribute to long-term customer relationships. |

|

Valuable customer feedback |

Helps identify issues and areas for improvement in logistics management. |

|

Reduced shipping costs and labor |

Leads to overall cost savings, enhancing operational performance. |

|

Increased customer satisfaction |

Results in higher return purchases and sales growth. |

|

Swift and cost-effective deliveries |

Achieved through real-time inventory visibility and intelligent order routing. |

|

Effective returns management |

Key to maintaining customer satisfaction and streamlining reverse logistics. |

Now is the time to embrace smarter logistics strategies. By doing so, you can transform your ecommerce operations, exceed customer expectations, and secure long-term growth in the competitive e-commerce landscape.

FAQ

What is the difference between a logistics center and a warehouse?

A logistics center handles multiple operations like inventory management, order processing, and shipping. A warehouse primarily stores goods. Logistics centers focus on streamlining the supply chain, while warehouses emphasize storage.

How can automation improve e-commerce fulfillment?

Automation speeds up repetitive tasks like picking, packing, and sorting. It reduces errors and labor costs while increasing order accuracy. For example, robotic systems can achieve over 98% accuracy in order fulfillment.

Why are micro-fulfillment centers important for e-commerce?

Micro-fulfillment centers store high-demand products closer to customers. This reduces delivery times and last-mile costs. They also enable same-day or next-day delivery, meeting modern consumer expectations for speed and convenience.

How does data-driven forecasting help in logistics?

Data-driven forecasting uses analytics to predict demand trends. It helps you stock the right products, avoid stockouts, and reduce overstocking. This improves inventory management and ensures smoother operations during peak seasons.

Should small businesses partner with third-party logistics providers (3PLs)?

Yes, 3PLs offer expertise, advanced technology, and scalability. They handle complex logistics tasks like shipping and returns, allowing you to focus on growing your business. This partnership reduces costs and improves customer satisfaction.

Related content